Blog, Company News

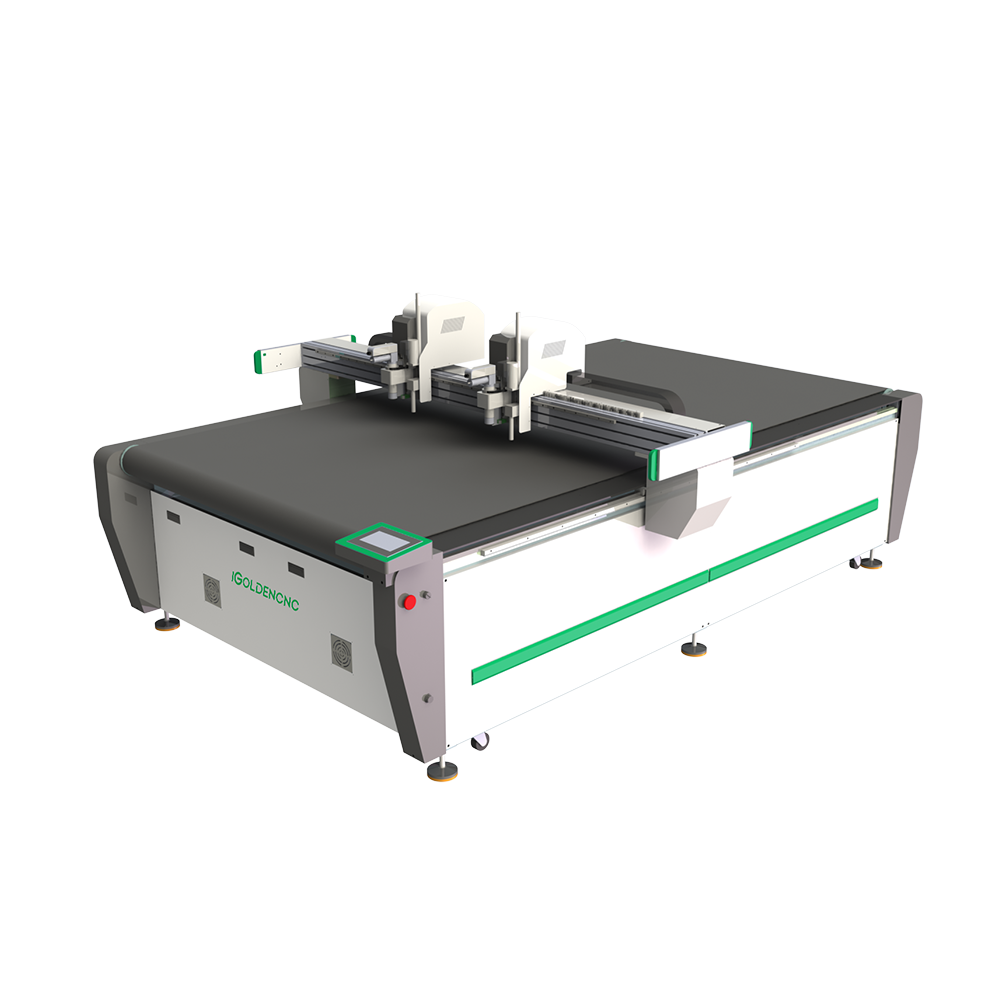

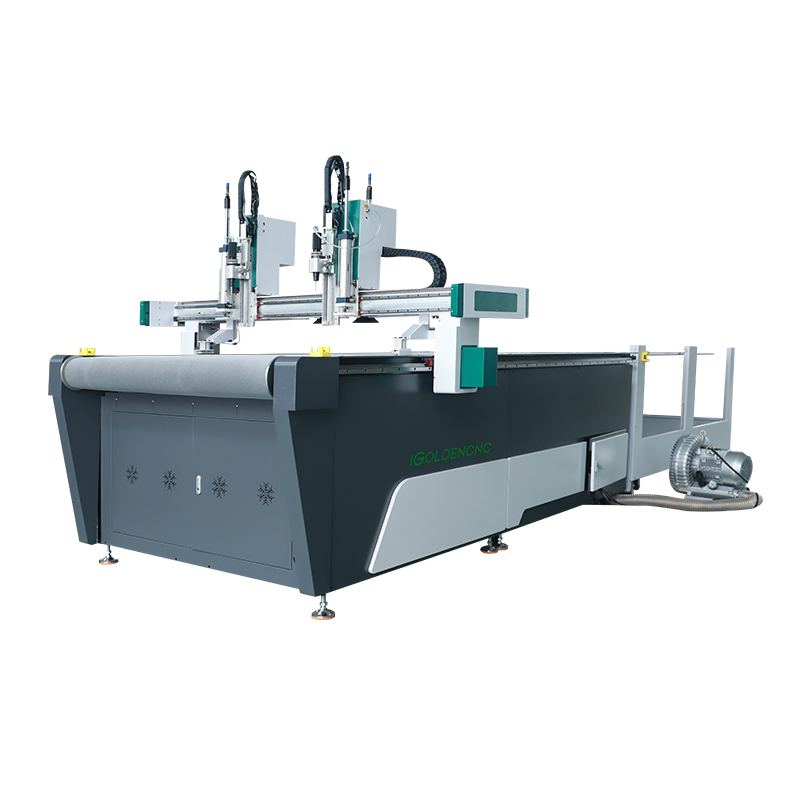

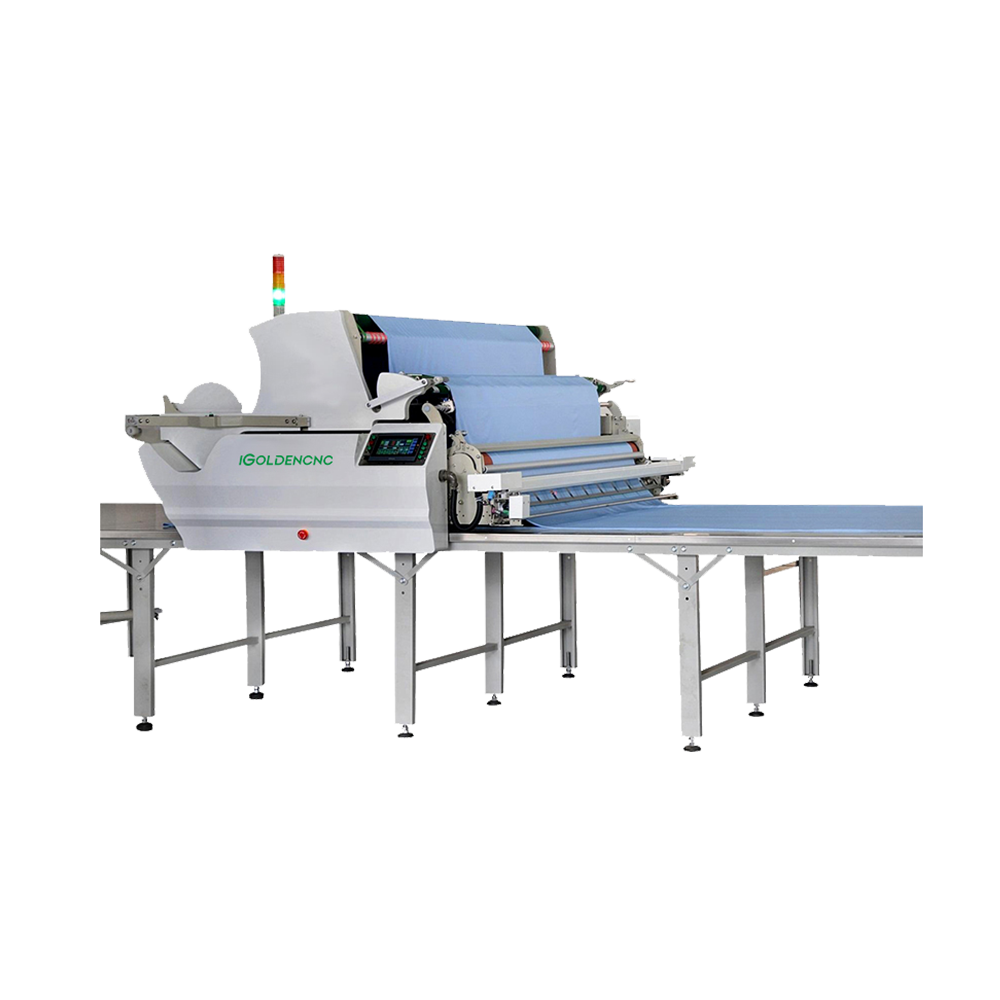

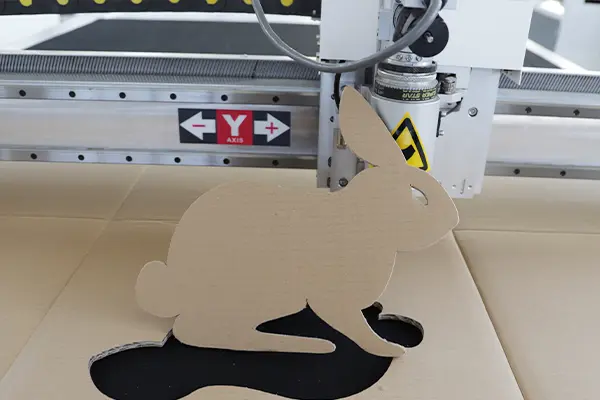

Flexible material cutting machine

Oscillating knife is an advanced cutting tool widely used for precise cutting of various materials, including foam, cardboard, leather, textiles, etc. Its high efficiency and precision make it popular in the manufacturing industry.

Advantages of Oscillating Knife

High precision: Oscillating knife can achieve high-precision cutting and reduce material waste.

Versatility: Suitable for a variety of materials and complex patterns.

High efficiency: Fast cutting speed and improved production efficiency.

Safe operation: Reduce safety hazards in mechanical operation.

Application areas

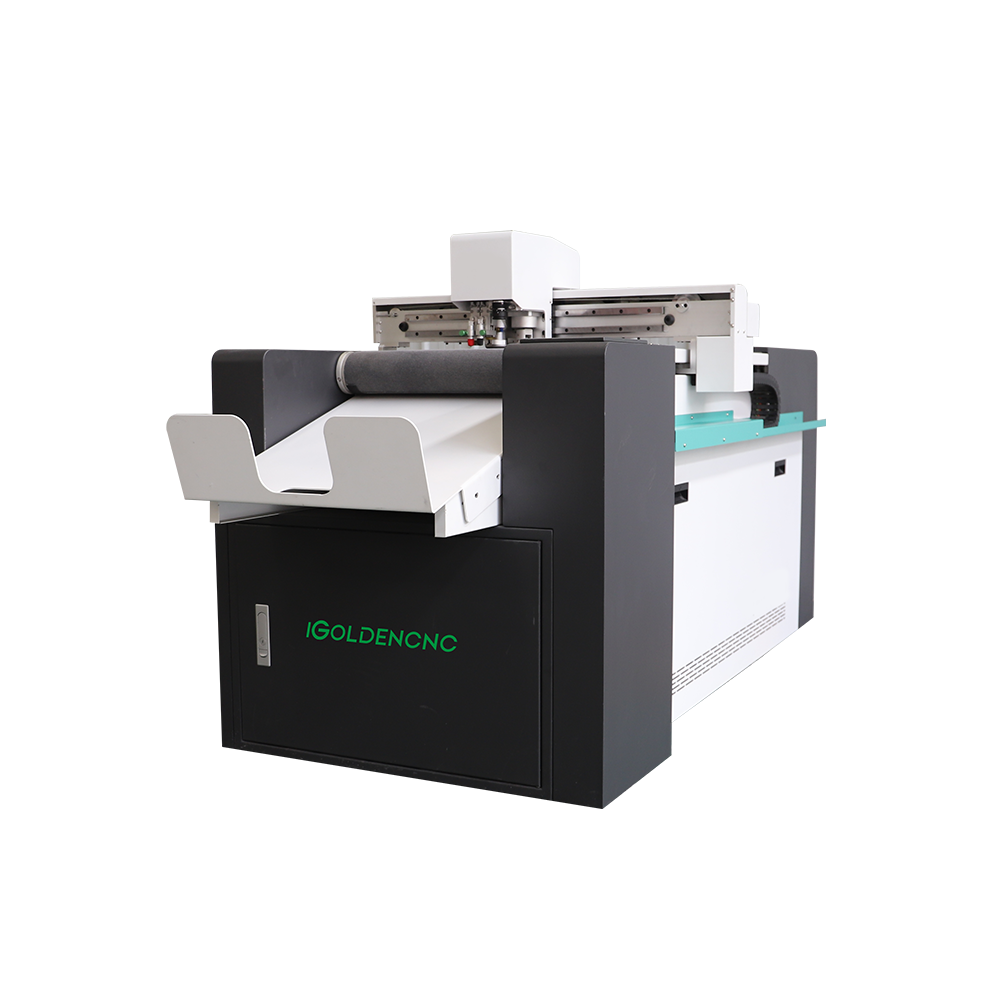

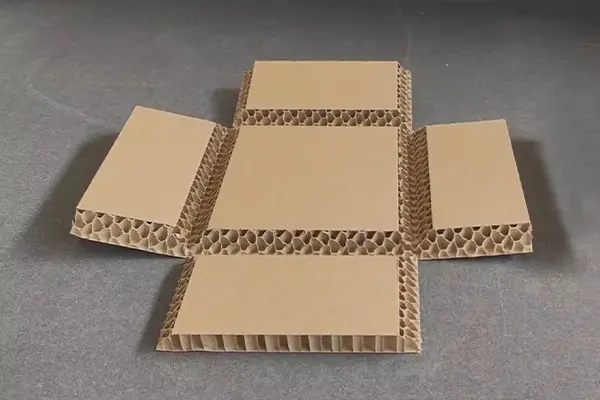

Packaging industry: Used to make various packaging materials.

Clothing industry: Cutting fabrics and making complex patterns.

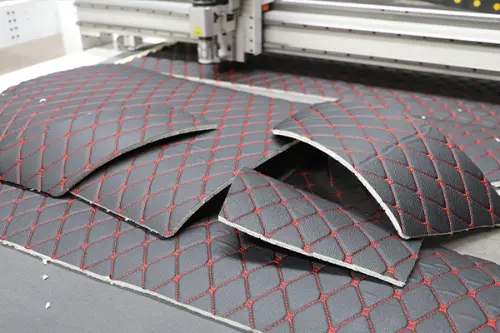

Automotive industry: Cutting interior materials.

Advertising industry: Making advertising boards and display materials.

Reasons for choosing an oscillating knife

When companies choose cutting tools, oscillating knives provide unparalleled flexibility and efficiency. For companies that require high precision and diverse cutting needs, oscillating knives are an ideal choice.

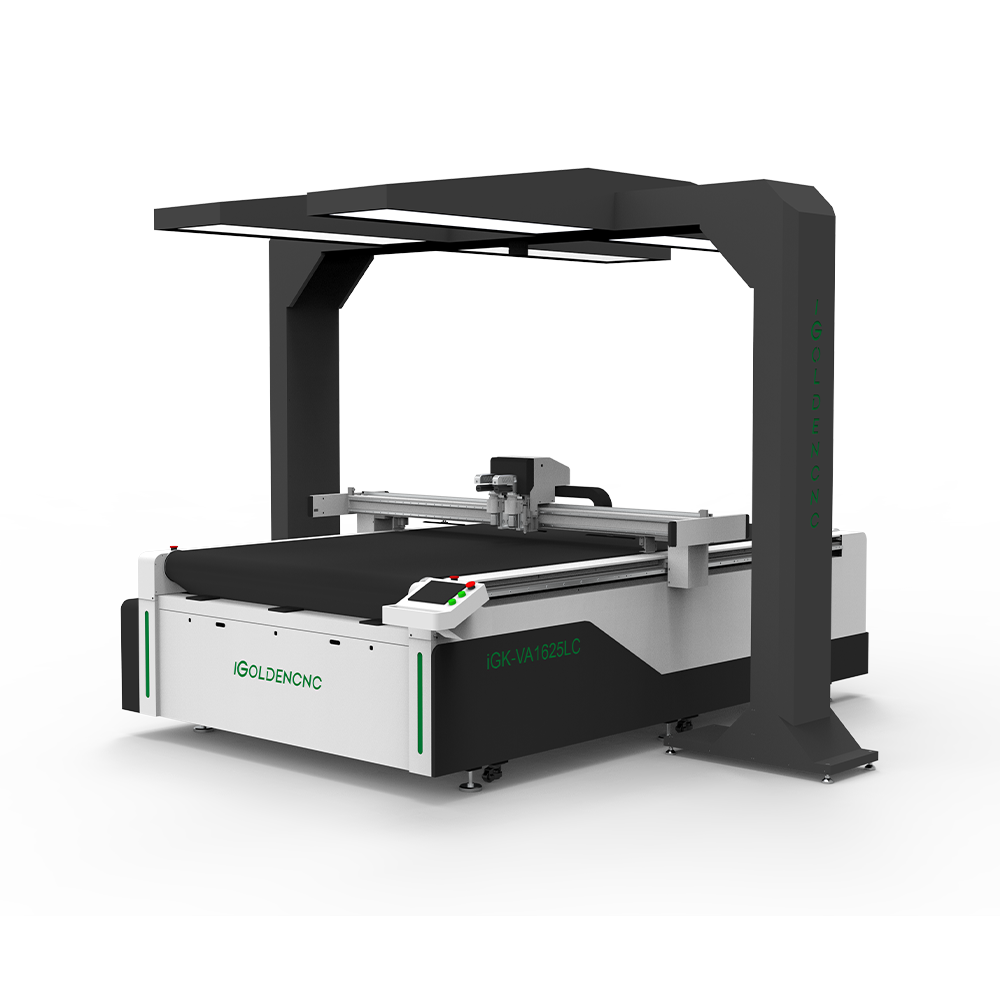

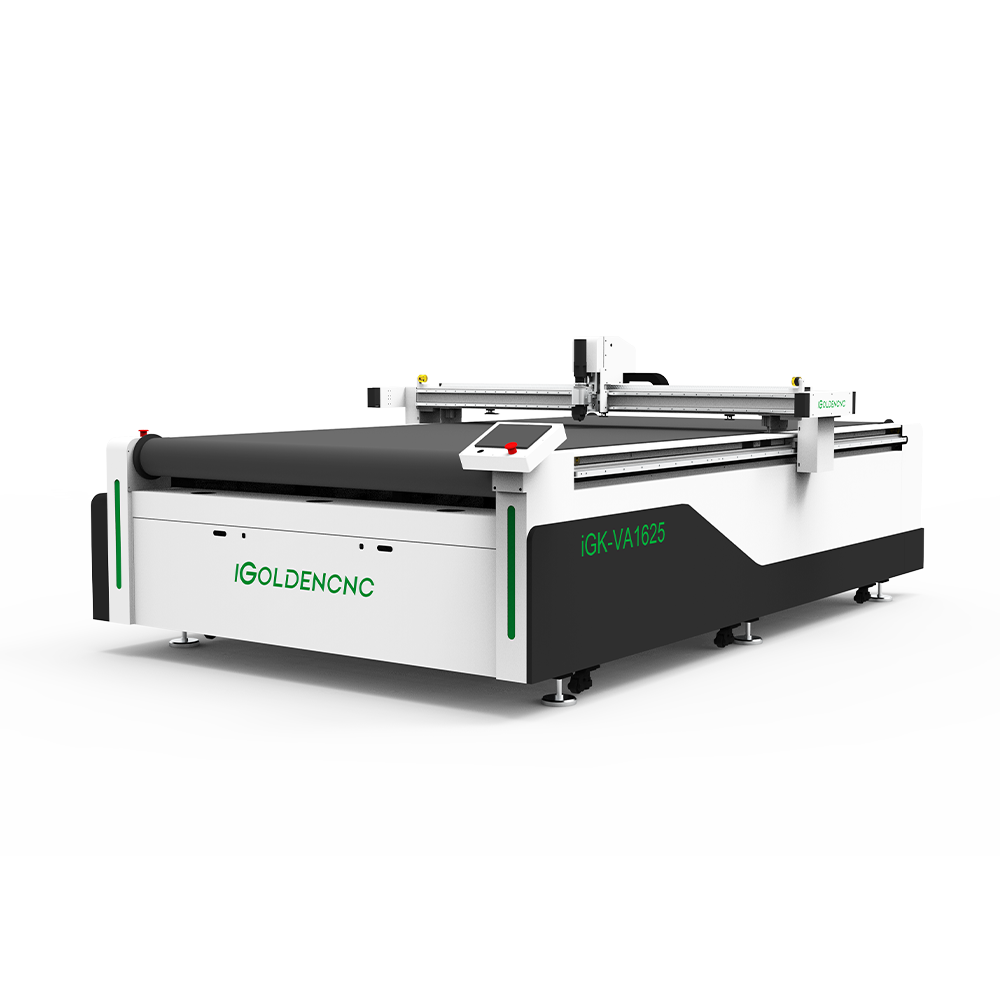

Model |

iGK-1625 (Size can be customized) |

| Working Size | 1600 (W) *2500mm (L) |

| Machine body | Welded high strength integrated bed |

| Platform adsorption material | 4mm felt |

| Tool | Vibrating knife |

| Cutting speed | 200-2600mm/s |

| Translatory velocity | 500-2800mm/s |

| Cutting thickness | 0.1-40mm (The actual materials shall prevail) |

| Cutting accuracy | 0.05mm (The actual materials shall prevail) |

| Can be matched with knives | Vibrating knives, round knives, punching knives, pneumatic knives, multi-layer knives, supporting knives, half cutters, bevel cutters, milling cutters, etc. |

| Applicable materials | Soft glass, PVC, leather, silk ring, silicone, rubber, KT board, car mats, flexible composite materials, cartons, insoles, luggage, clothing, outdoor products, curtain fabrics, tablecloth fabrics, etc. |