Blog

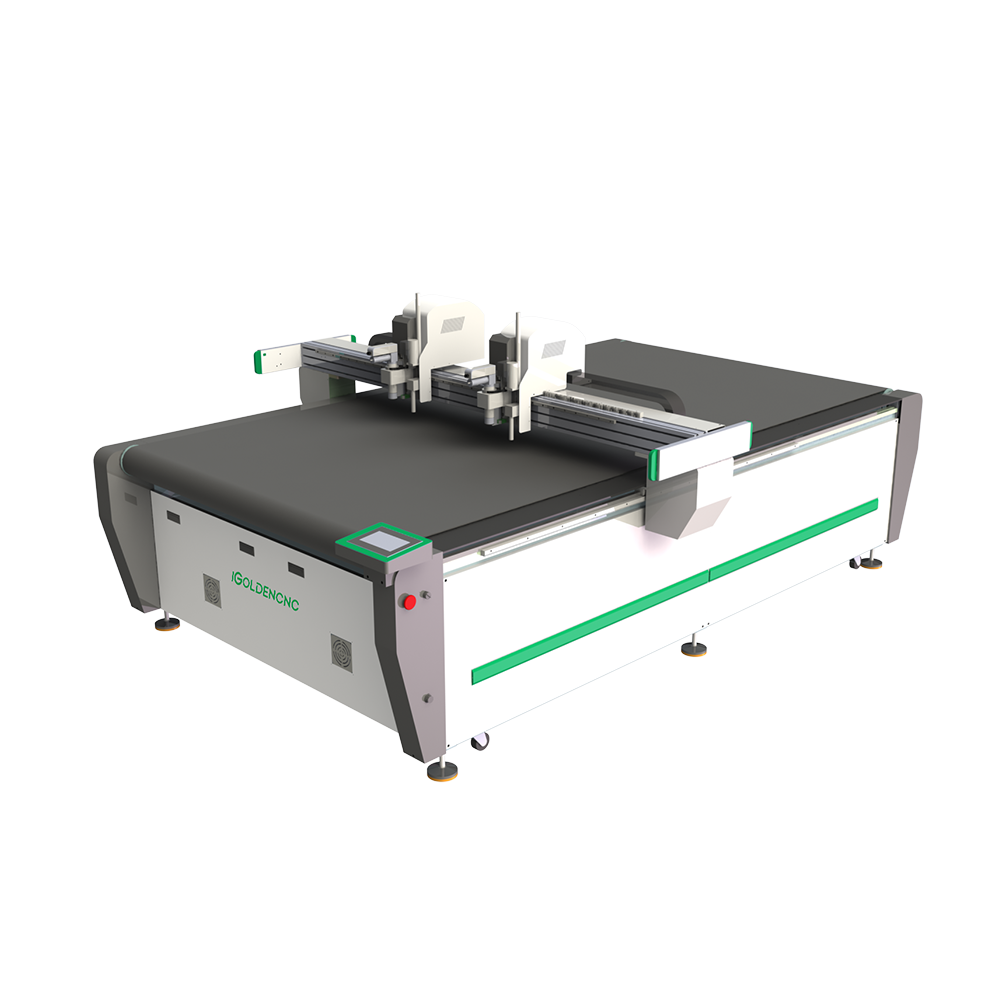

My Vibrating Knife Cutter Experience: An Efficient, Economical, and Eco-friendly Perfect Choice

As an entrepreneur with many years in the manufacturing industry, I have always been on the lookout for solutions that can enhance production efficiency, reduce costs, and ensure employee safety. Recently, I decided to try out the vibrating knife cutter for our flexible material cutting needs. After using it for a while, I’d like to share my thoughts and experiences.

Features

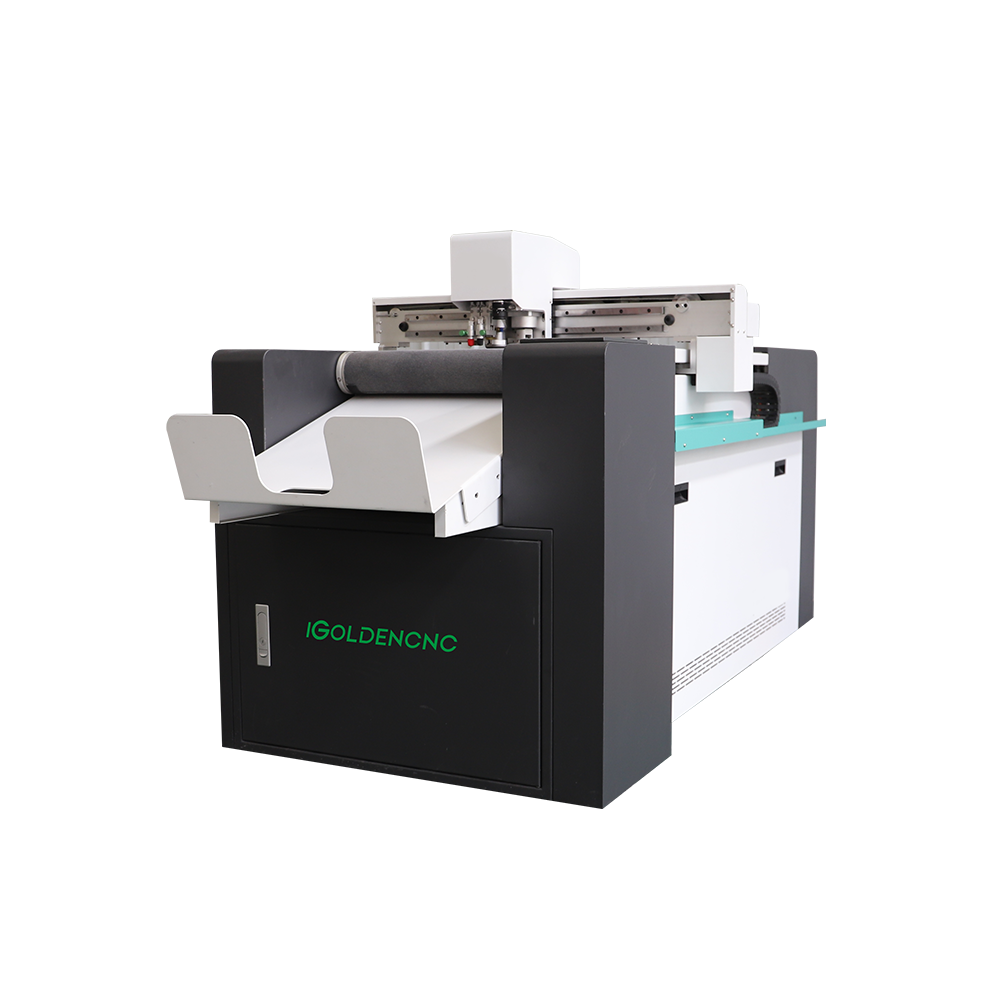

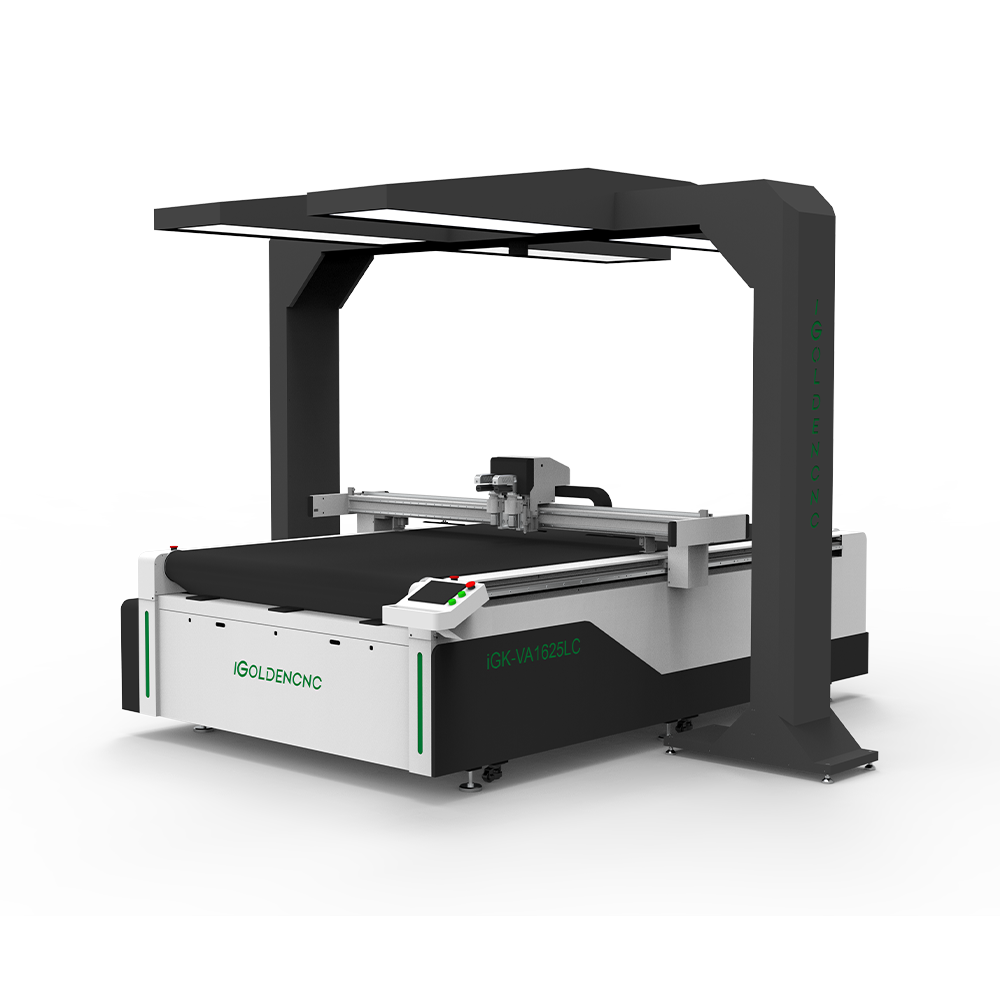

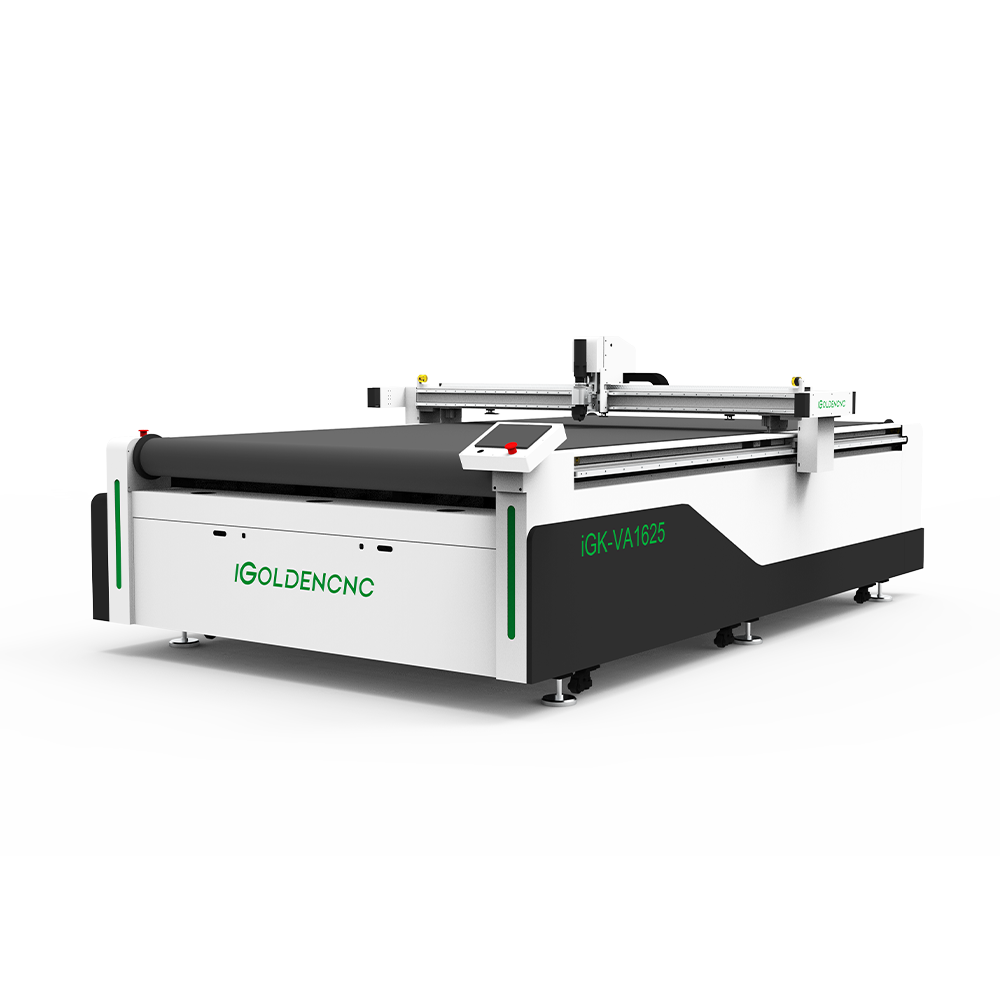

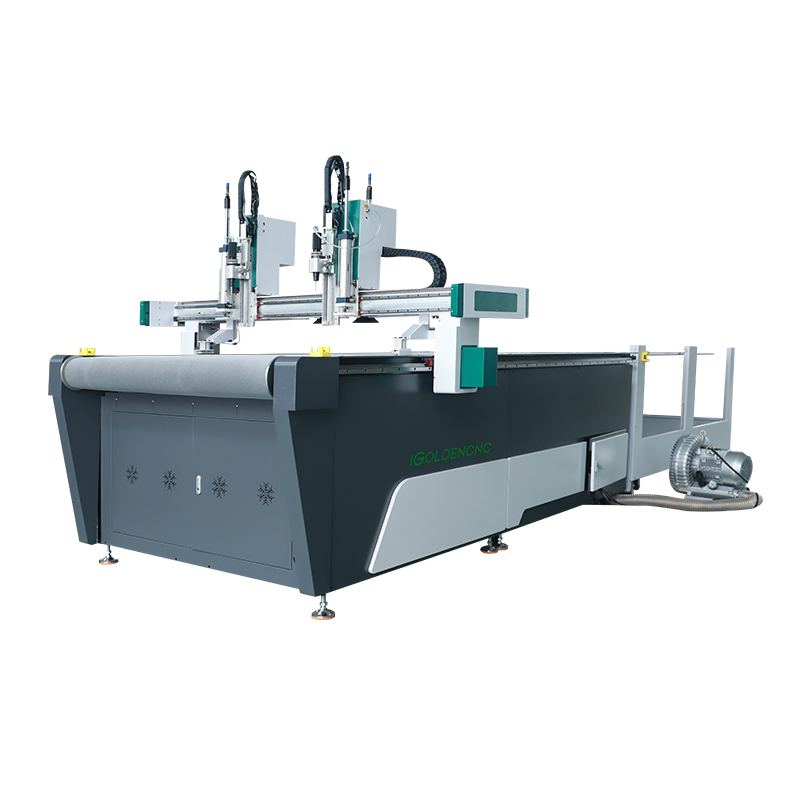

1.High-Precision Cutting: The vibrating knife cutter uses blade technology to achieve a cutting accuracy of ±0.01mm, ensuring the finesse of the cut quality. This high precision allows it to meet the demands of various complex shapes and detailed cuts.

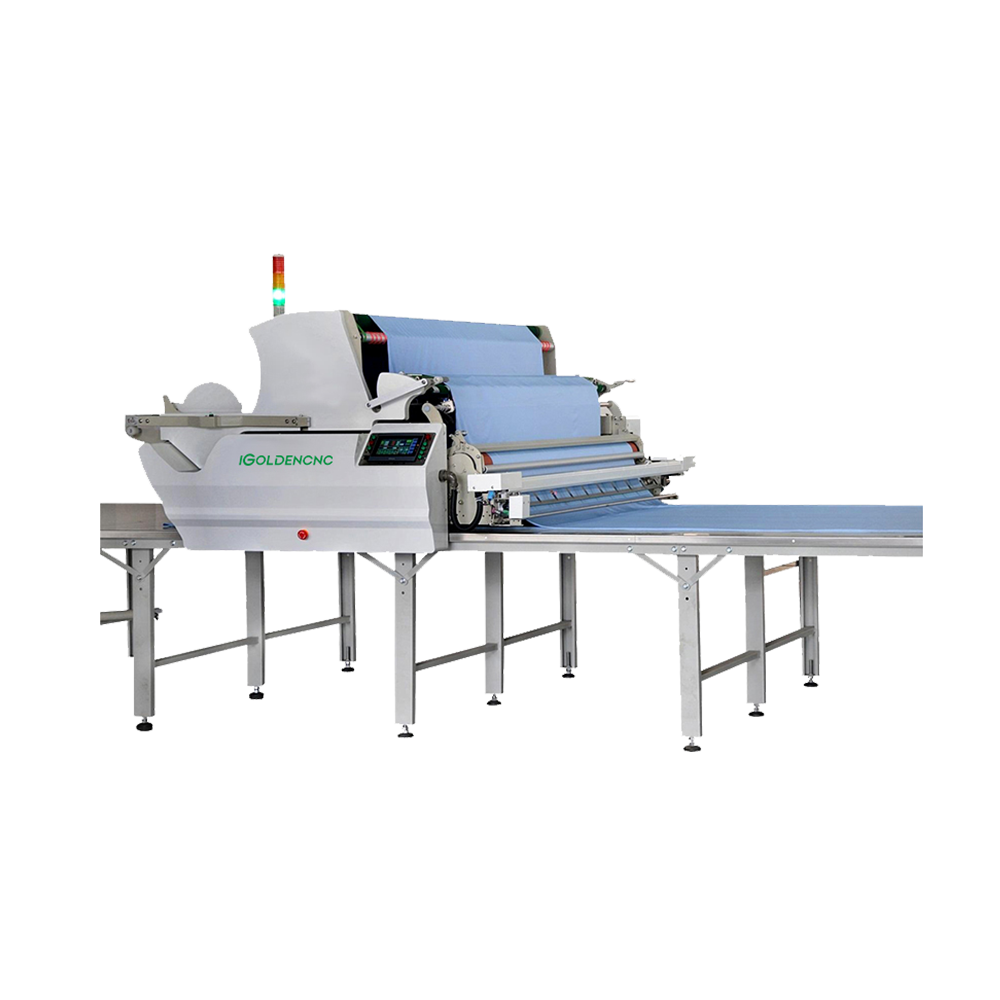

2.Eco-friendliness: The machine operates without heat sources, smoke, pollution, burnt edges, or frayed ends, making it more eco-friendly compared to thermal cutting devices. This is particularly important for industries requiring clean working environments.

3.Safety Performance: The unit is equipped with an anti-static system, infrared sensors, and a Schneider safety button. With all electrical components imported and the body made from square tube welding and aviation aluminum alloy splicing, it offers comprehensive protection for personnel safety. These measures ensure the safety of operators during use.

Advantages & Benefits

1.Improved Product Quality: The high precision of the vibrating knife cutter results in smoother and cleaner edges, eliminating the need for secondary trimming and thus enhancing the final product quality.

2.Reduced Production Costs: Compared to laser cutting machines, vibrating knife cutters do not require expensive lasers or lenses, leading to lower maintenance costs. Additionally, their high efficiency means more work can be completed in a shorter time, further reducing production costs.

Increased Work Efficiency: Equipped with a Panasonic servo system, the production speed reaches 2500mm/s, replacing the work of 4-6 manual workers and significantly boosting work progress.

Better Working Environment: Since there is no heat source, the vibrating knife cutter does not produce smoke or odors during operation, providing a more comfortable working environment for employees.

3.Enhanced Safety: Multiple safety measures ensure the safety of operators during use, reducing the occurrence of work-related injuries.

.

Evidence

Since introducing the vibrating knife cutter, our production line efficiency has significantly increased, and the product quality has received high praise from our customers. More importantly, our employees are very satisfied with the new working environment because they no longer have to worry about harmful smoke or odors. Additionally, both our maintenance and labor costs have decreased, making us more competitive in the market.

Conclusion

In conclusion, I am very satisfied with the performance of the vibrating knife cutter. It not only improved our production efficiency but also helped us reduce costs and improve the working environment. I believe that for any business looking to enhance its competitiveness, the vibrating knife cutter is an ideal choice.