Blog

What Tools Can Be Used to Cut EVA Foam?

1. Traditional EVA Foam Cutting Tools

Utility Knives/Handheld Cutters

- Pros: Low cost, suitable for simple DIY projects.

- Cons:

- Uneven edges requiring sanding.

- Limited to 2D shapes; struggles with complex curves.

- Labor-intensive for bulk orders.

Hot Wire Cutters

- Pros: Smooth edges for basic 3D shapes (e.g., foam props).

- Cons:

- Melting fumes pose health risks.

- Slow speed (5-10 minutes per detailed piece).

- Difficulty maintaining consistency across batches.

Laser Cutters

- Pros: High precision for intricate designs.

- Cons:

- Thermal damage causes burnt edges and toxic smoke.

- Limited to thin EVA sheets (typically <10mm).

- High maintenance costs (laser tube replacement).

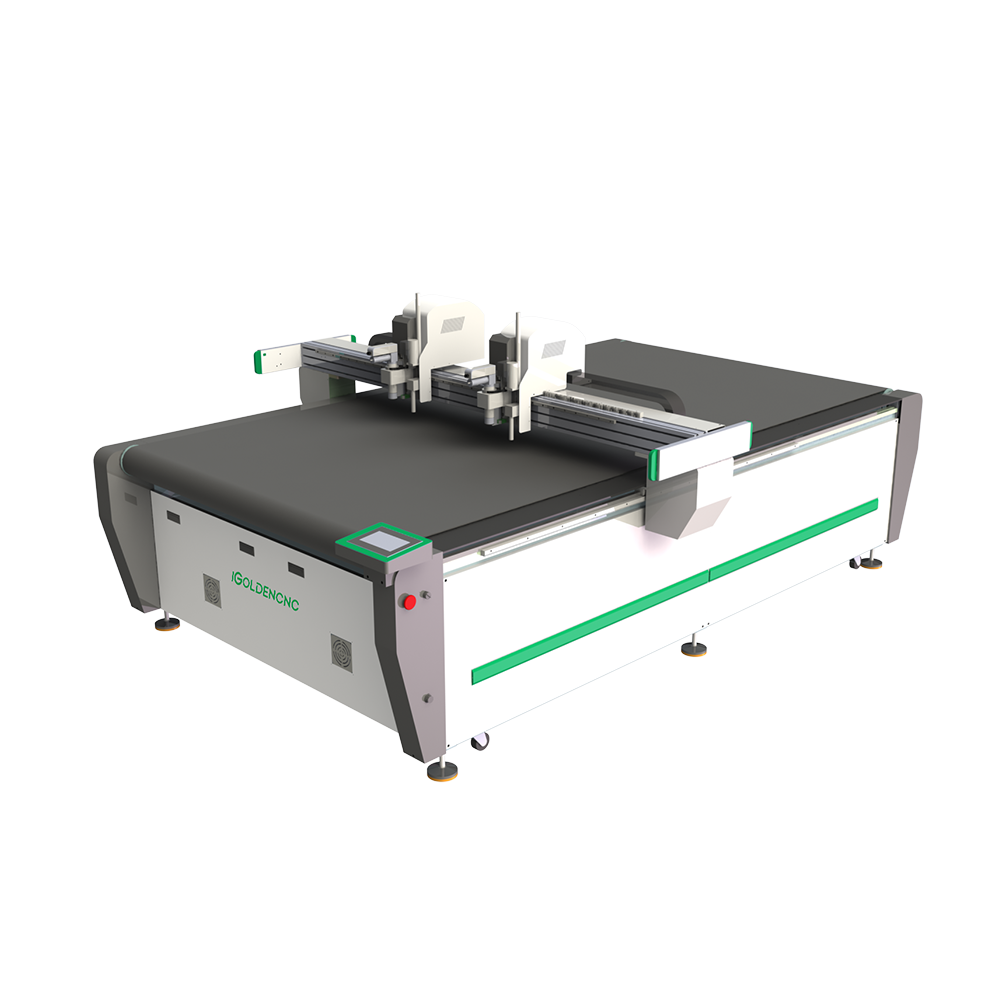

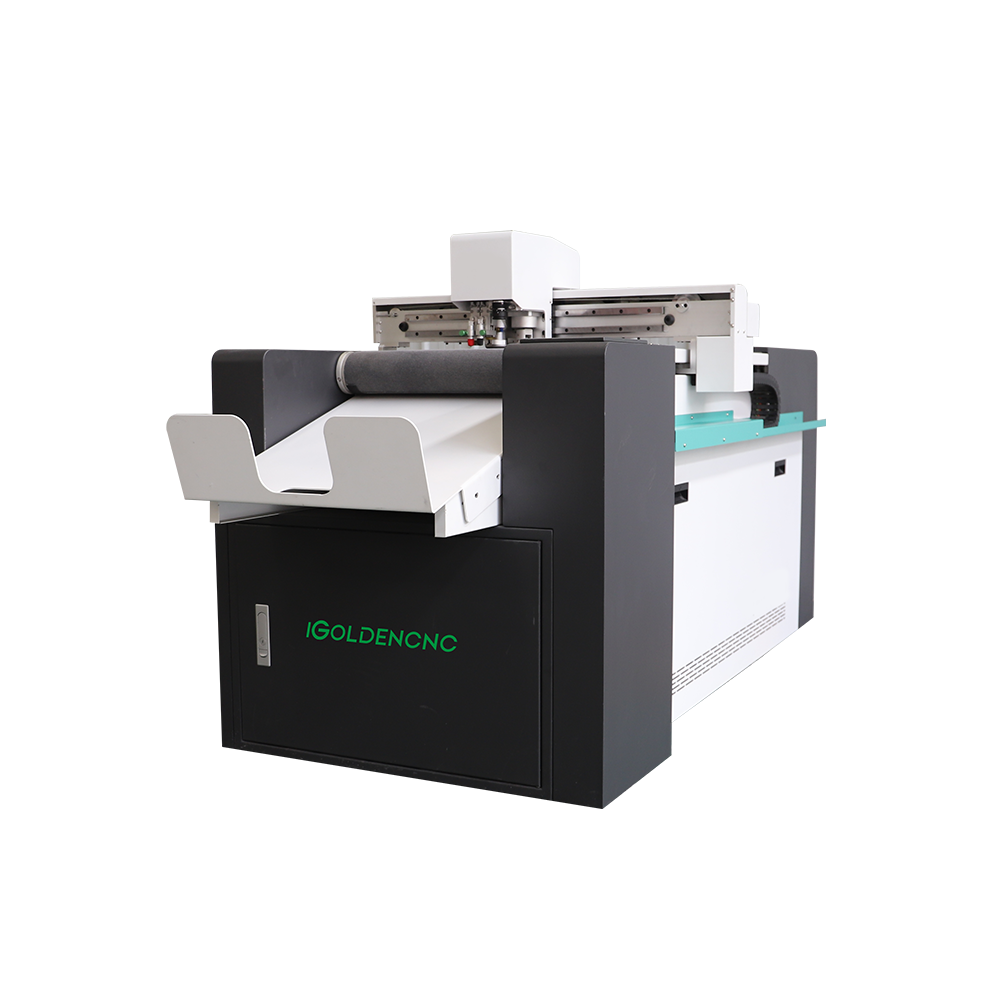

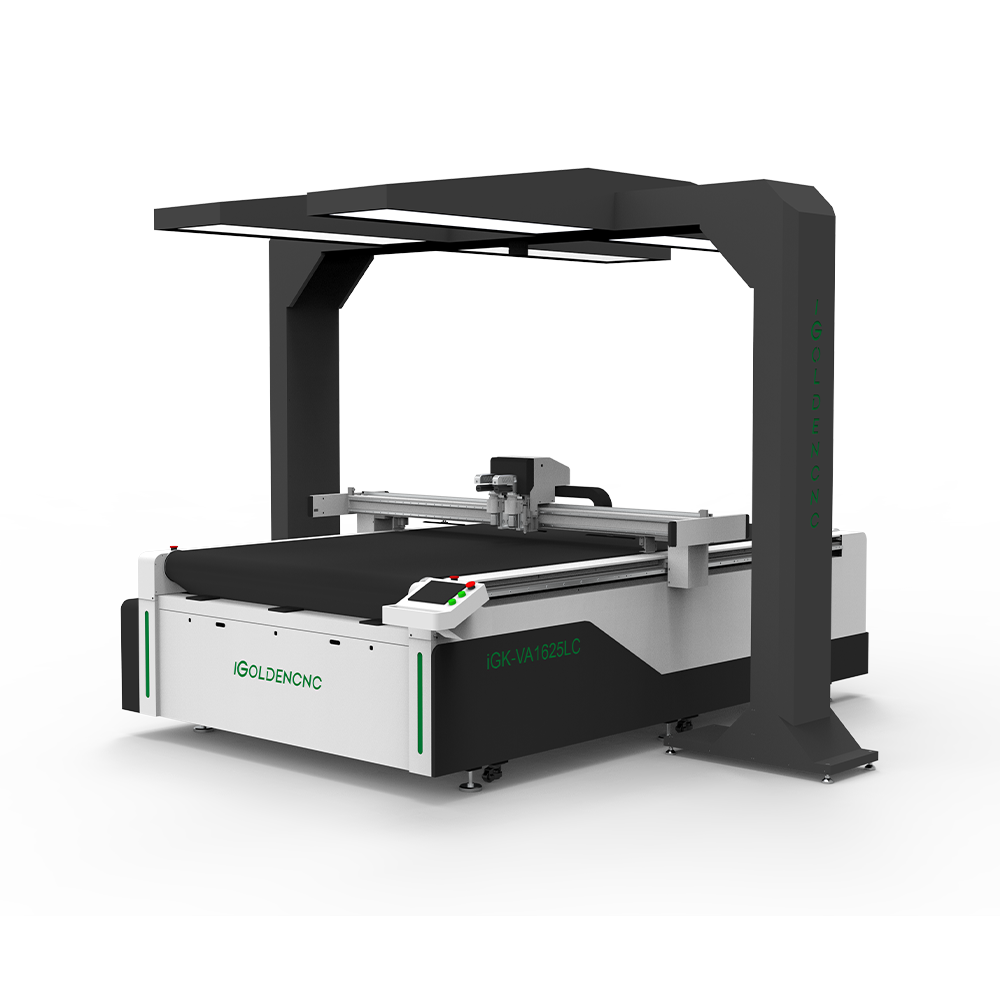

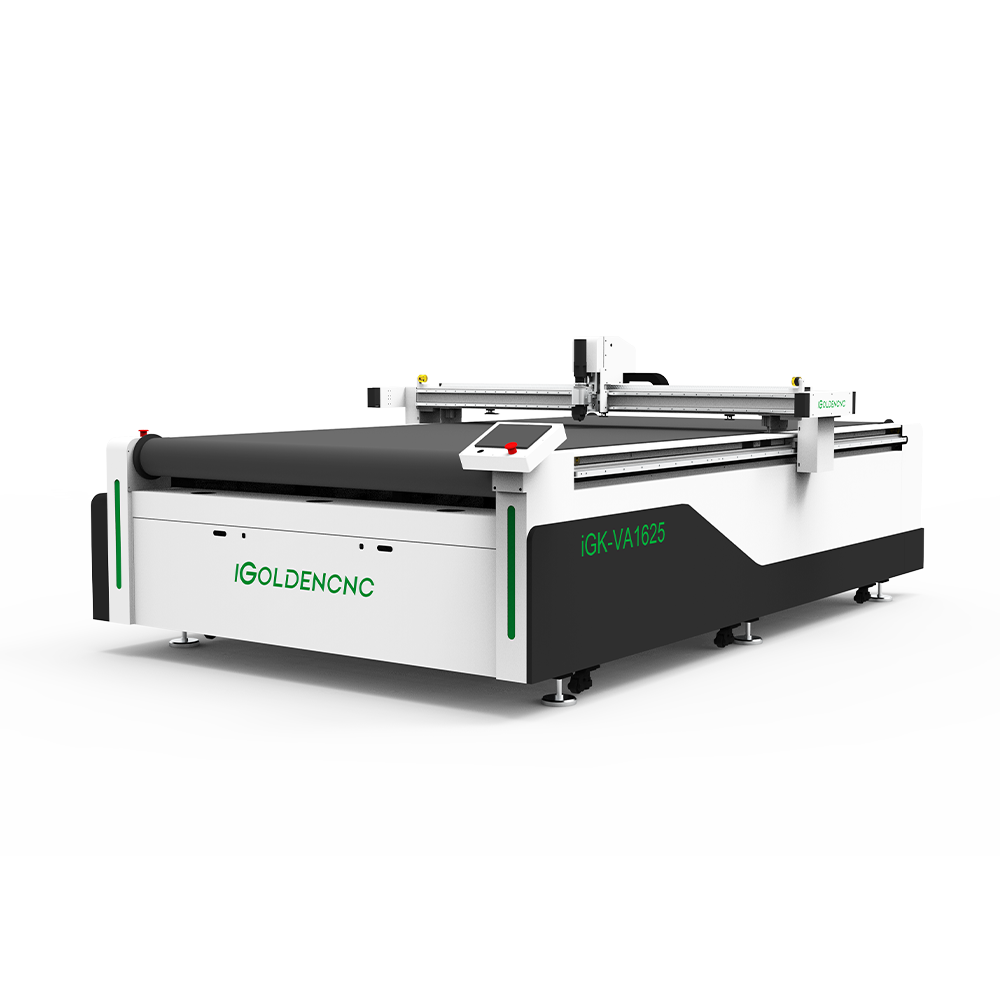

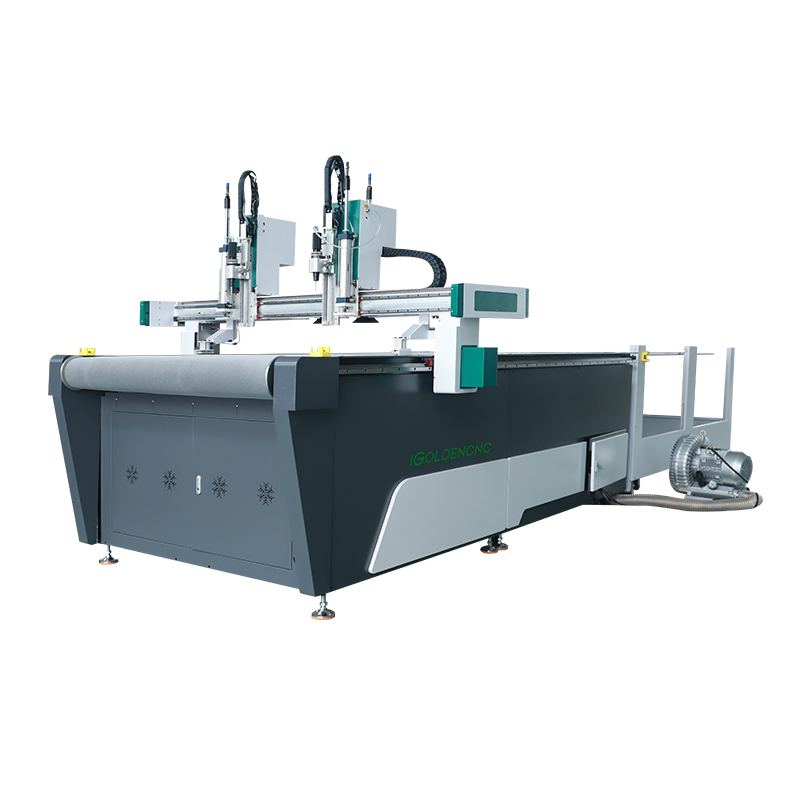

2. Why Vibrating Blade CNC Cutters Excel in EVA Foam Cutting

Cold Cutting Technology

- No Heat Damage: Ultrasonic vibrating blades slice through EVA foam without melting or deformation, preserving material integrity.

- Thickness Adaptability: Cuts EVA from 1mm to 50mm effortlessly—ideal for thick shock-absorbing pads or delicate cosplay details.

AI-Optimized Efficiency

- Nesting Software: Automatically arranges patterns to reduce material waste by up to 25%.

- Speed: 3X faster than laser cutters (e.g., 100 shoe insoles in 15 minutes).

Multi-Layer Cutting Capacity

- Stack 10-20 EVA sheets in one pass with vacuum table fixation, ensuring identical shapes for mass production.

Cost Savings

- No Consumables: Blades last 10X longer than laser tubes.

- Zero Mold Costs: Directly import CAD files for instant cuttin

4. Applications of Vibrating Blade-Cut EVA Foam

- Footwear: Custom orthopedic insoles with seamless edges.

- Sports Gear: High-density foam pads for helmets/knee guards.

- Industrial Packaging: Shock-absorbing inserts for fragile goods.

- Creative Industries: Detailed cosplay armor and props.