Blog

Why choose a vibrating knife to cut gaskets?

Gaskets can play a role in buffering, sealing and shock absorption, and are widely used in machinery manufacturing, automobiles, electronics, construction, chemicals, aerospace, electricity, medical equipment, home appliances, new energy and other industries

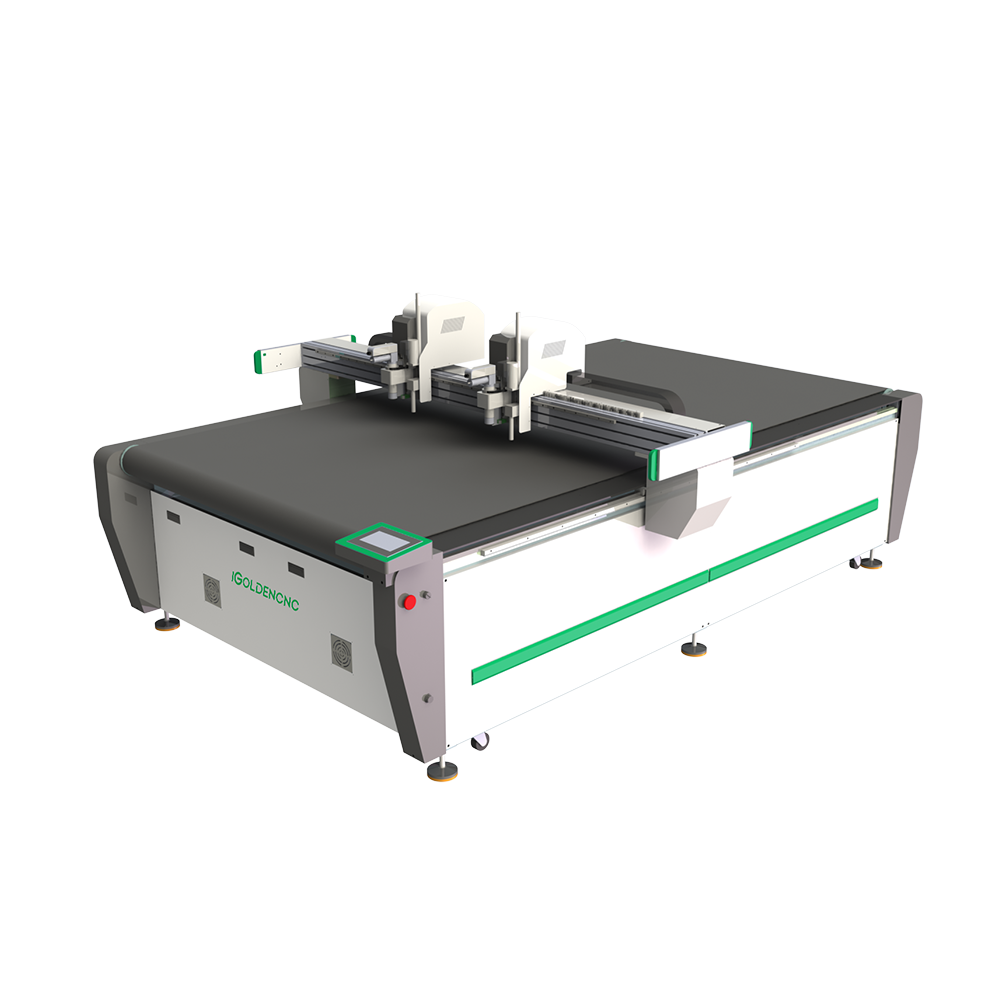

In machinery manufacturing and industrial applications, precision and efficiency are essential. Vibrating knife gasket cutting machine is an indispensable tool when cutting gaskets. Why choose us to meet your gasket cutting needs? Here are some reasons to choose us:

1. Deep industry accumulation and practical accumulation

Our company has many years of experience in the field of industrial cutting solutions. We are a manufacturer specializing in vibrating knife cutting equipment, ensuring that our products are designed and manufactured to the highest standards. Our team of experts is proficient in the complexity of gasket cutting and can provide you with precise and reliable machines.

2. Cutting-edge technology research and development strength

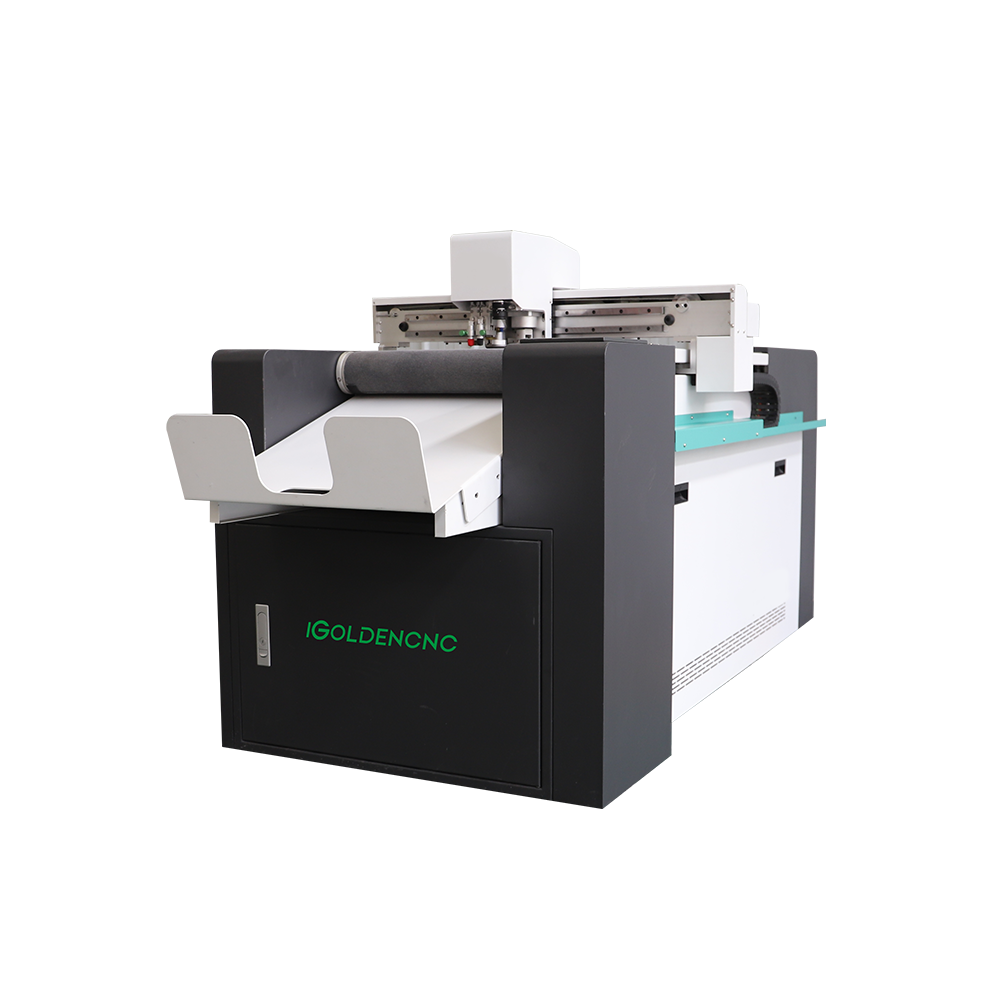

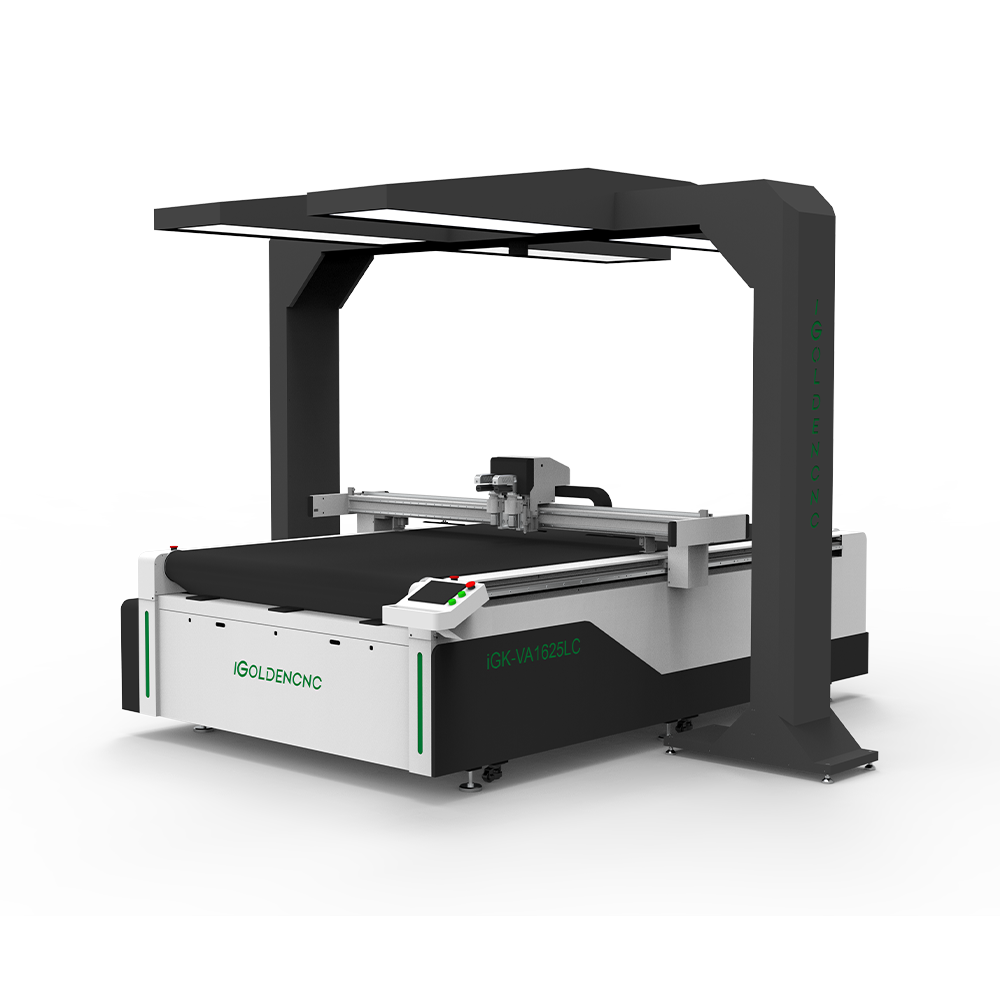

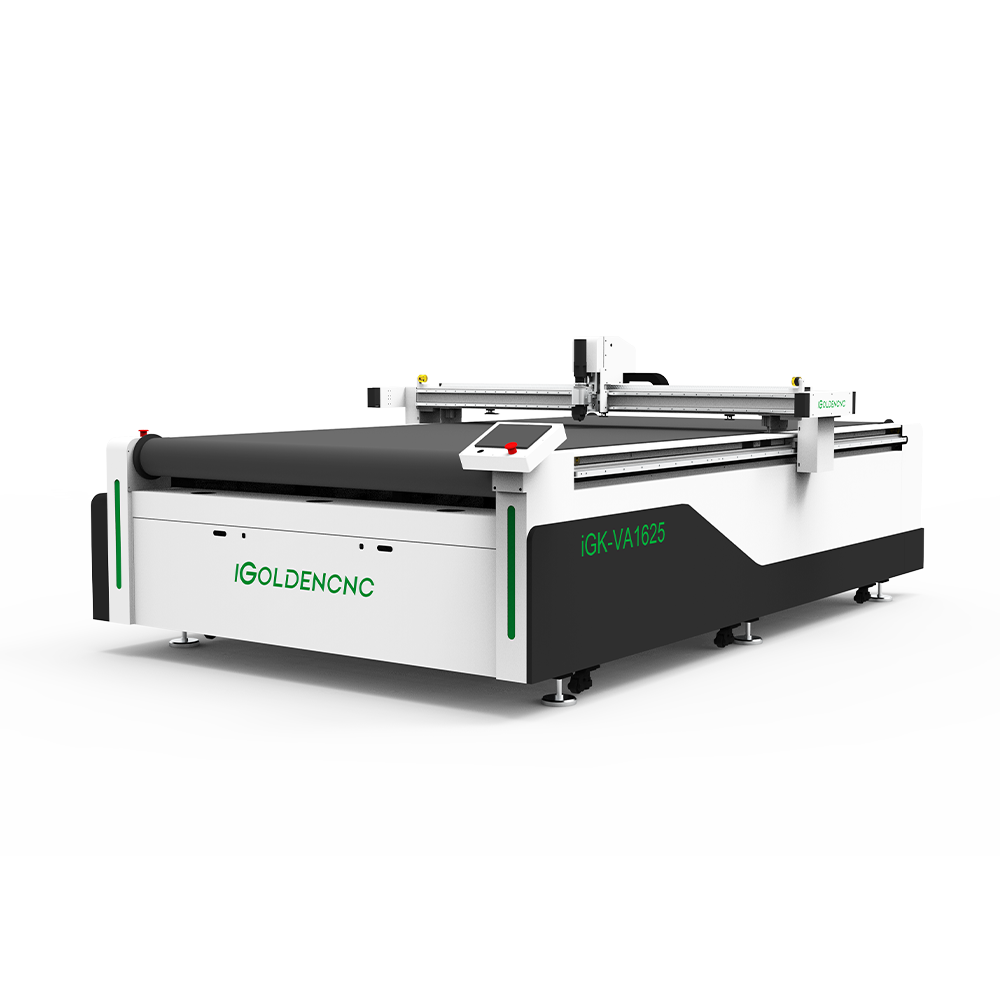

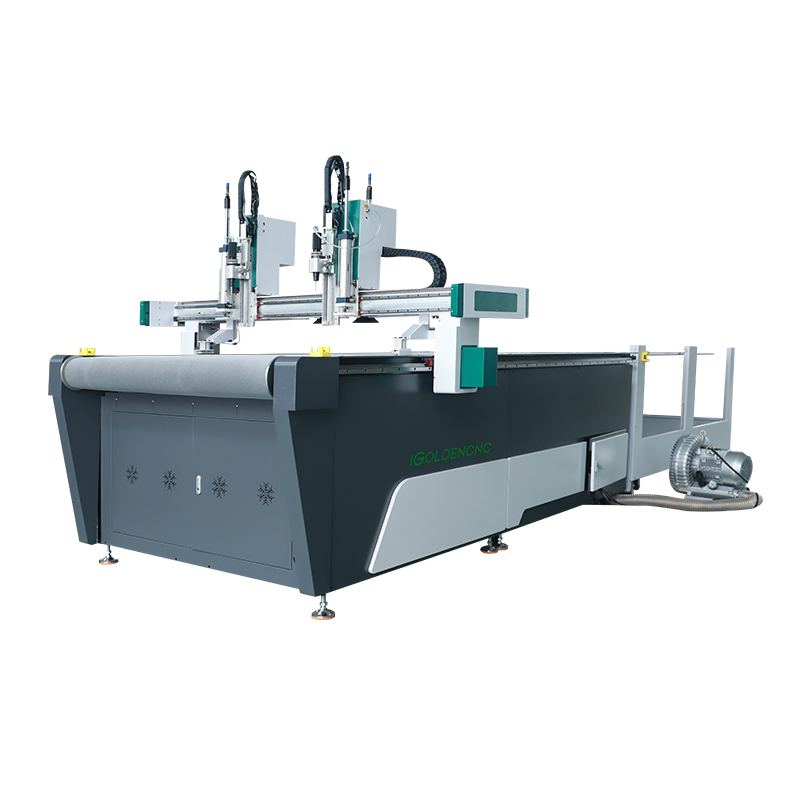

We use the latest technology to design vibrating knife gasket cutting machines. Our machines are equipped with advanced features such as automatic control, high-speed cutting capabilities and user-friendly interfaces. This ensures that the machine you get is not only efficient but also easy to operate, thereby reducing downtime and improving production efficiency.

3. Highly flexible personalized configuration scheme

Every industry has unique requirements, and we know that a one-size-fits-all approach doesn’t work. That’s why we offer customized options for our vibrating knife gasket cutters. Whether you need a specific cutting size, a specialized blade, or other features, we can customize our machines to meet your specific needs.

4. Full-cycle customer success system

Our commitment to customer satisfaction goes beyond just providing high-quality machines. We provide excellent customer support from initial consultation to after-sales service. Our team is always available to answer any questions you may have, ensuring your use goes smoothly.

5. Optimal cost-effectiveness ratio

Quality does not have to be high-priced. We offer vibrating knife gasket cutters at competitive prices to make your investment worthwhile. Our transparent pricing model ensures that you get the best price with no hidden fees.

6. Verifiable excellent delivery results

We have a proven track record of providing reliable and efficient vibrating knife gasket cutters to a wide range of industries. Customer satisfaction proves our commitment to quality and customer satisfaction.

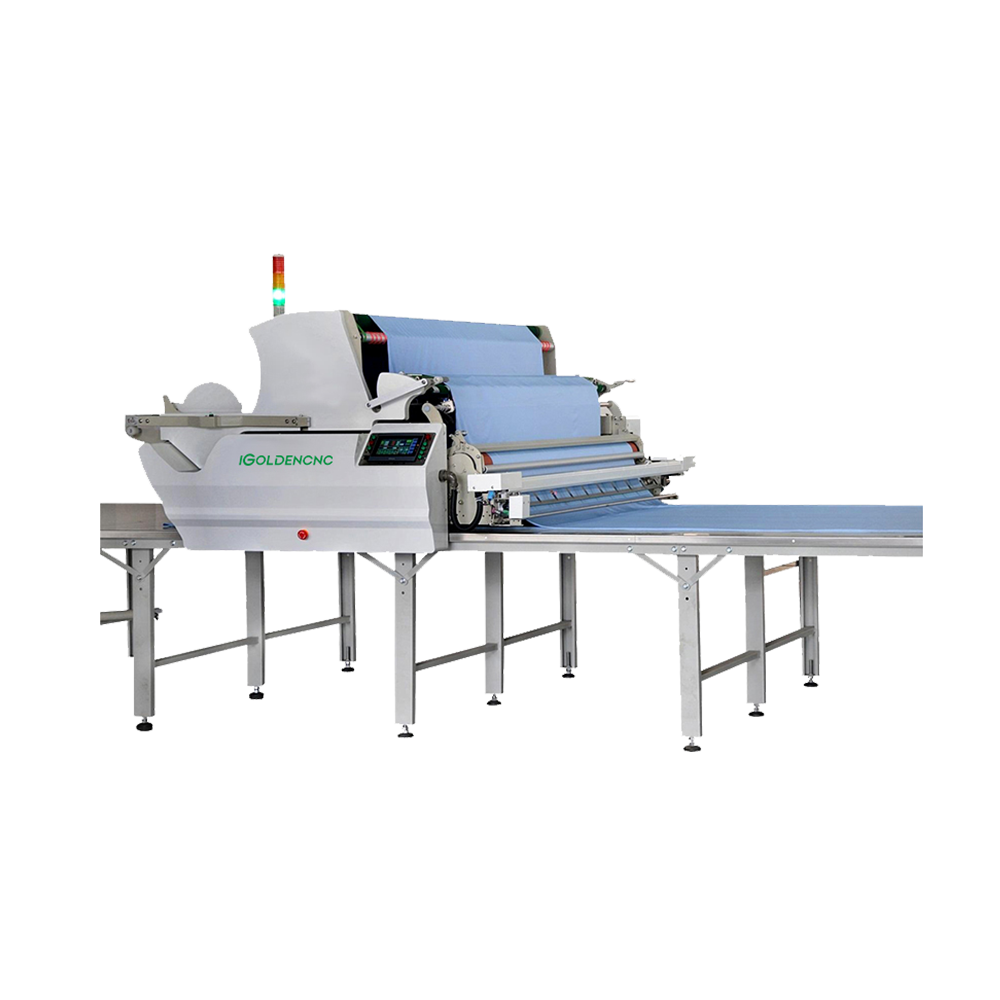

As the application of gaskets becomes more and more extensive, the shapes and sizes of gaskets required by customers are becoming more and more diverse, and small batch orders are increasing. The factory cannot refuse such production orders and needs to find a more flexible and intelligent production method to meet the production of small batches and multiple styles of gaskets, and solve the problems of high mold production costs and long production cycles.

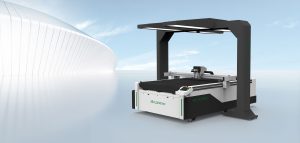

The igoden CNC gasket cutting machine perfectly solves the problem of customized gasket cutting. Using CNC cutting mode, no mold is required. Just transfer the designed graphics to the computer, and use the intelligent nesting system to quickly manage the cutting graphics and quantity, obtain the best material utilization, and ensure perfect cutting accuracy without secondary processing.

The igoden intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.