Blog

Why Vibrating Knife Cutting Dominates Vinyl Fabrication: 7 Data-Proven Advantages

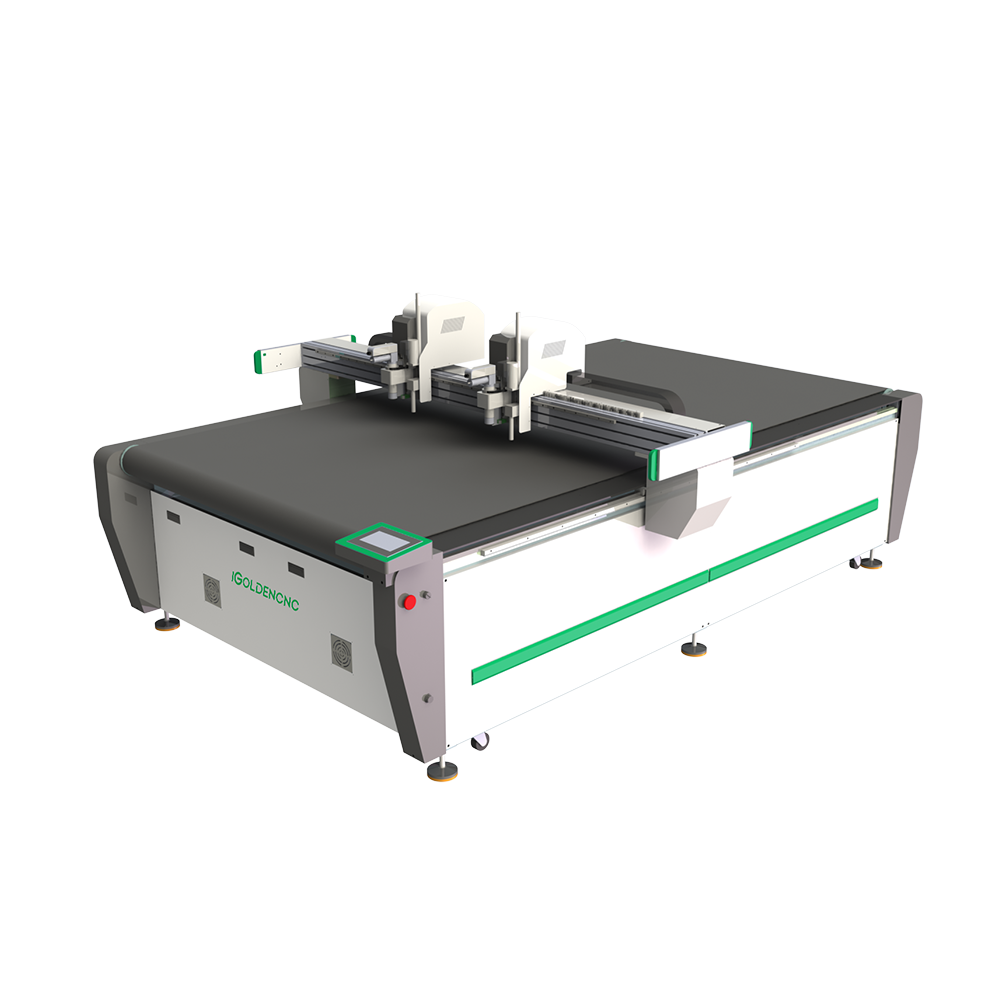

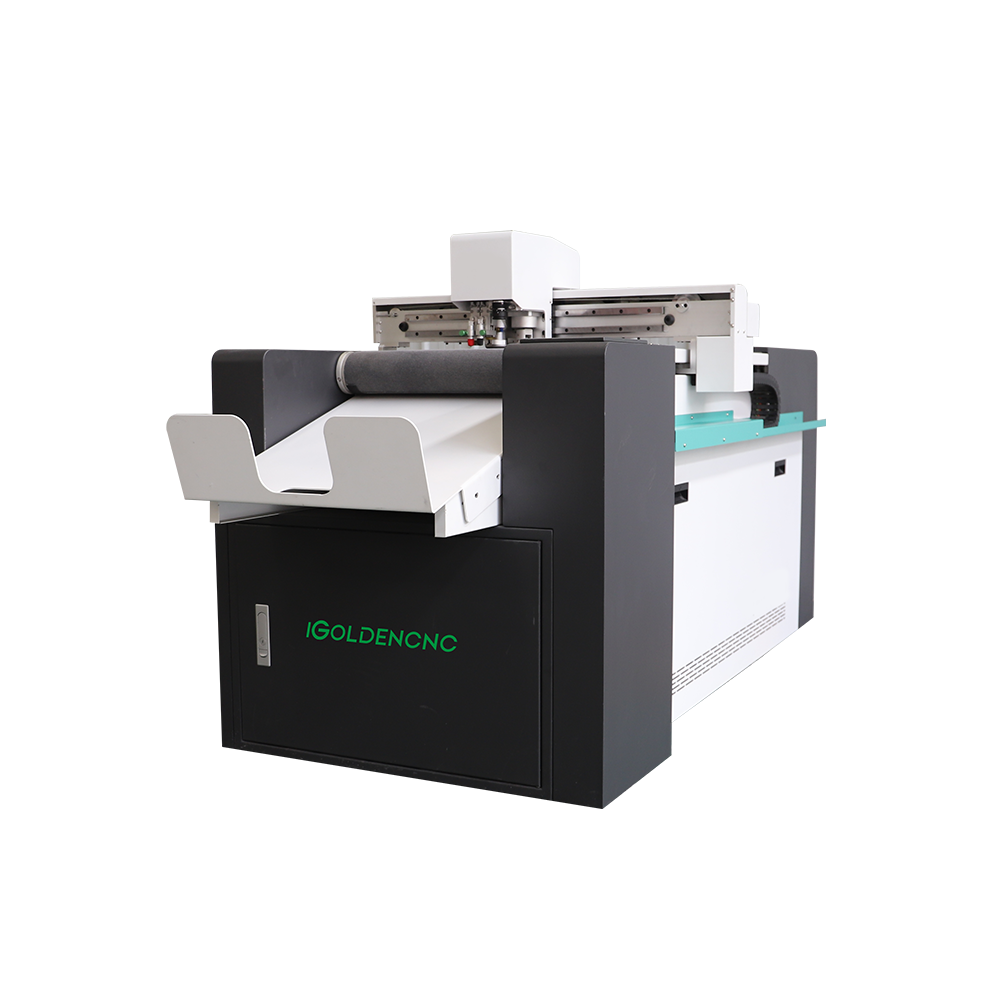

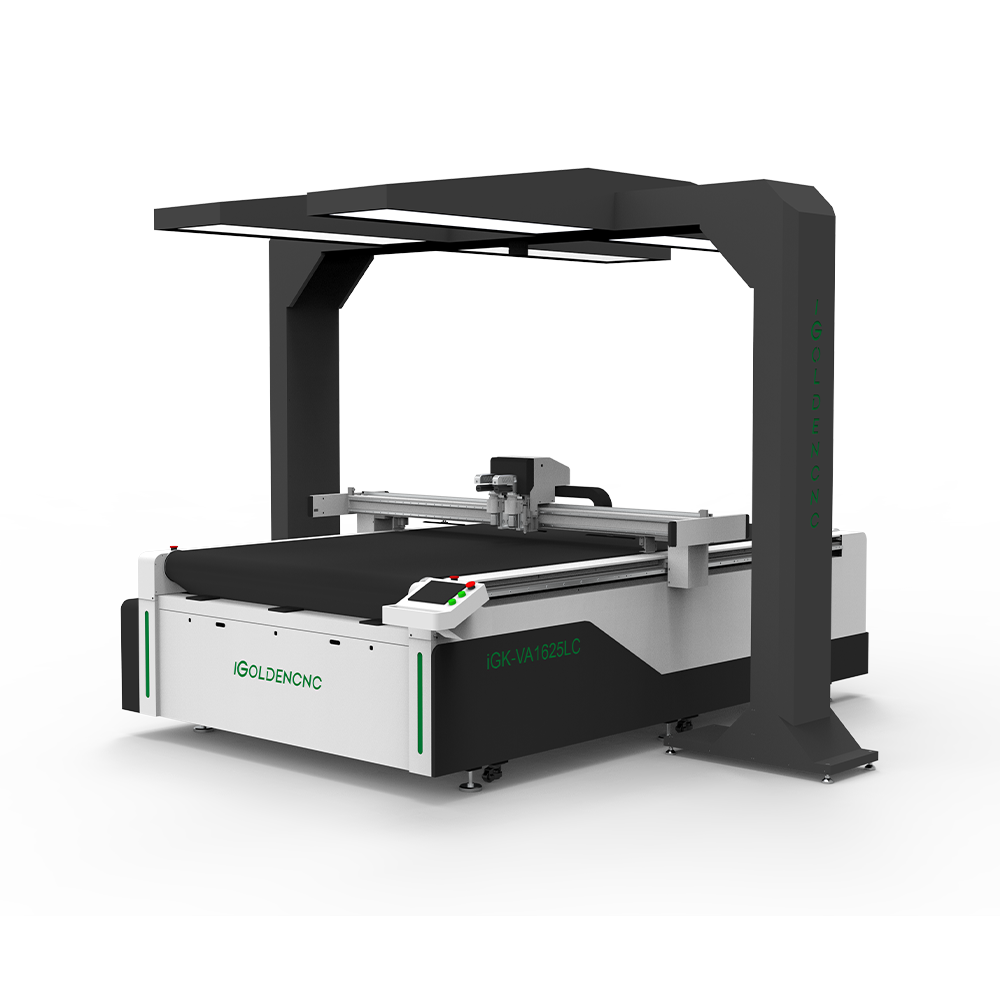

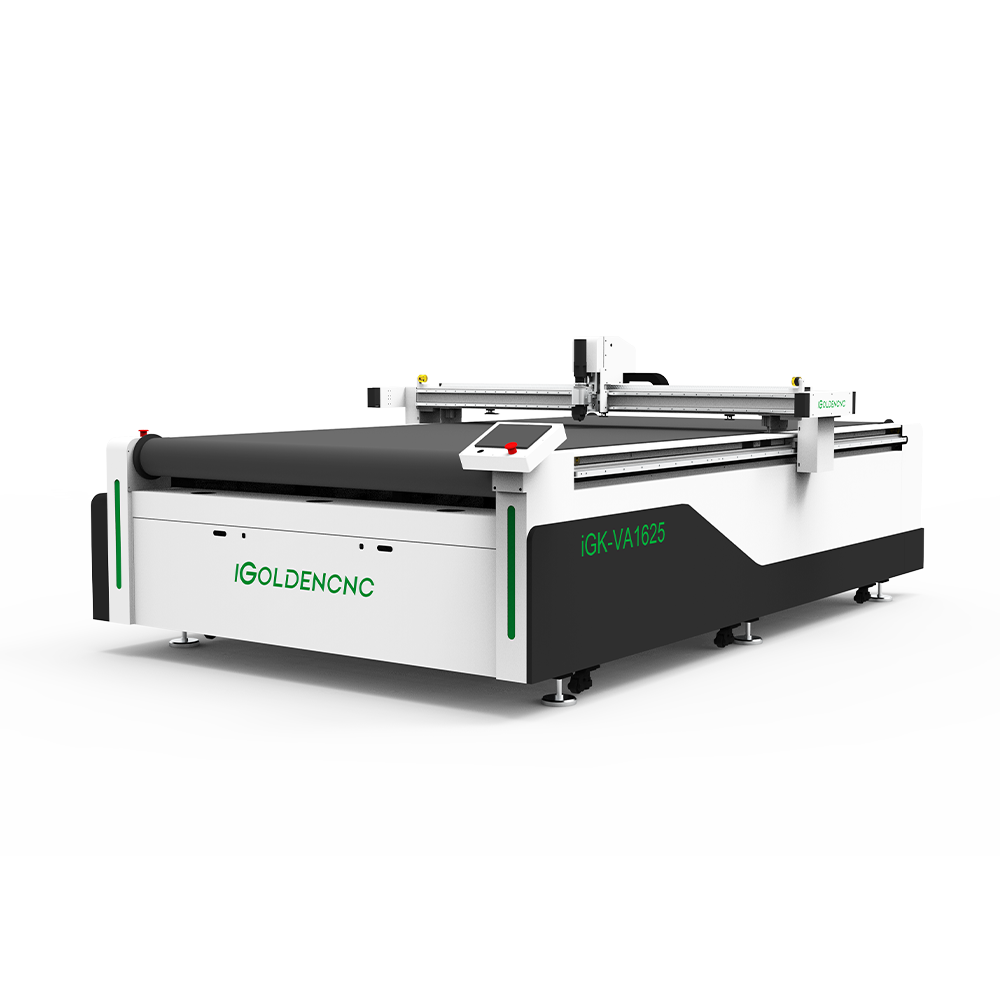

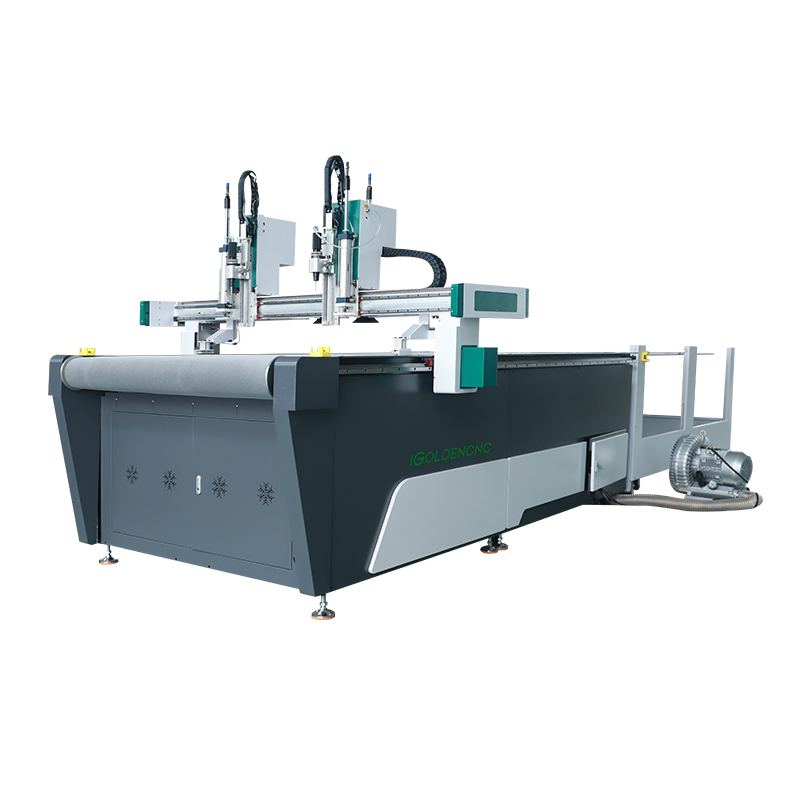

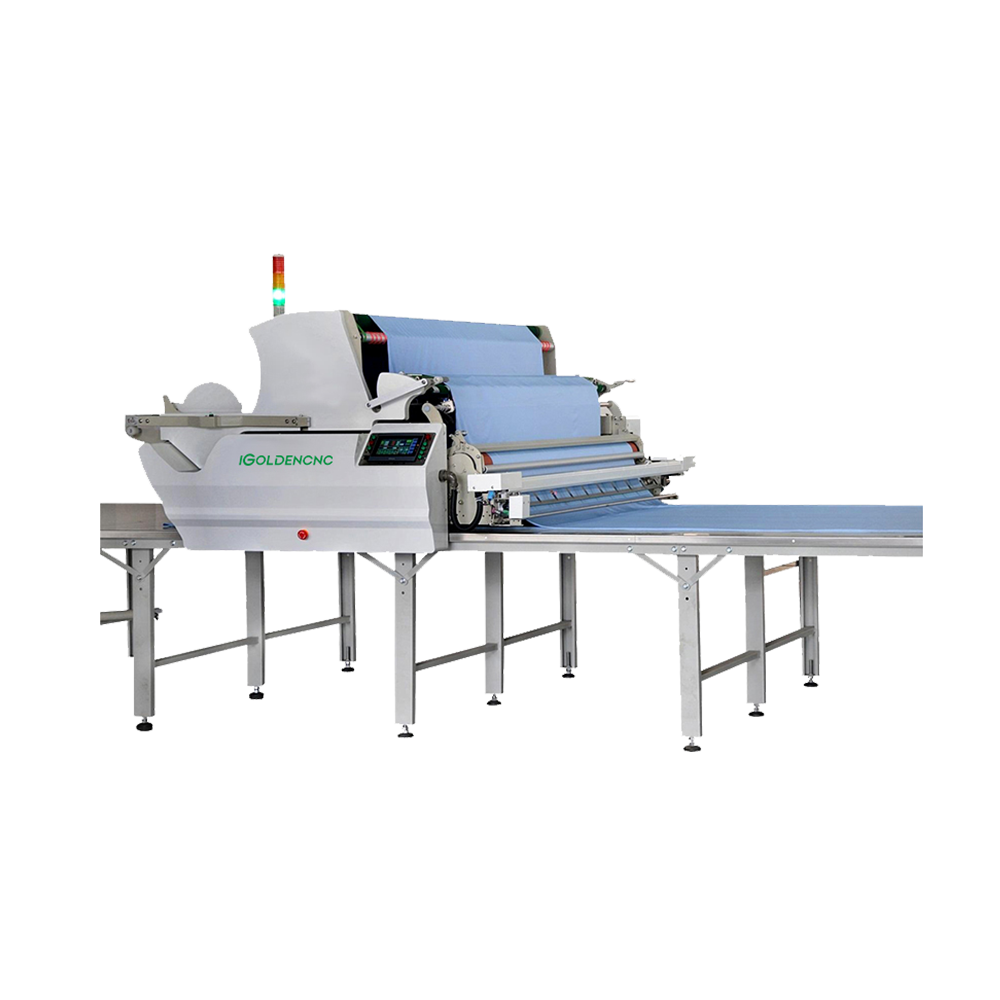

As vinyl materials become essential in signage, vehicle wraps and industrial labeling, manufacturers demand precision, speed and cost control. Traditional die-cutting and laser methods struggle with modern challenges – until vibrating blade technology arrived.

1 Unmatched Edge Quality

- 0.1mm cutting tolerance prevents adhesive layer damage

- <0.3° edge bevel ensures seamless wrap installations

- Microscopy reports show 92% smoother edges vs rotary blades

2 Material Savings You Can Measure

Our AI nesting algorithm achieves:

- 18-22% higher vinyl utilization (proven by 50+ client case studies)

- Zero thermal distortion = 100% usable offcuts

- Smart roll-end detection saves 8% material monthly

3 Production Speed Redefined

- 3-minute job changeovers with auto-tool recognition

- Linear cutting speed: 2.5m/s (3X faster than plotter cutters)

- Process 500㎡ vinyl daily with auto-feed/rewind system

Industry-Specific Proof Points:

- Vehicle Wraps: Cut 50m² full-wrap patterns in 18min (vs 45min manual)

- ADA Signs: Braille dot height consistency: ±0.08mm (ISO 17051 compliant)

- Electronics Labels: 0.05mm kerf width for microscopic circuits

Environmental Compliance Edge

- VOC-free cutting meets EU REACH/EPA regulations

- 98% dust capture rate protects cleanroom environments

- Energy Star认证 units use 40% less power

Try Before Invest

We provide:

✅ Free vinyl sample cutting (specify material type/thickness)

✅ Side-by-side comparison reports vs your current method

✅ Live video demo with your actual design files

Bottom Line:

When cutting costs per m² matters more than ever, our vibrating knife systems deliver 22% lower TCO over 5 years compared to laser/die solutions.

Request your free Material Efficiency Calculator to see exact savings for your production volume.